Combustion drives power plants, boilers, engines, and incinerators. Getting the balances right controls fuel economy, emissions, and safety. In this lesson you will learn how to compute theoretical air, percent excess air or oxygen, equivalence ratio, and product gas composition for real fuels.

Nature of Combustion Reactions

Combustion is a general term for a broad range of industrial processes that involves a redox reaction with oxygen. It is characterized by the release of stored chemical energy and formation of oxides. It follows the general reaction:

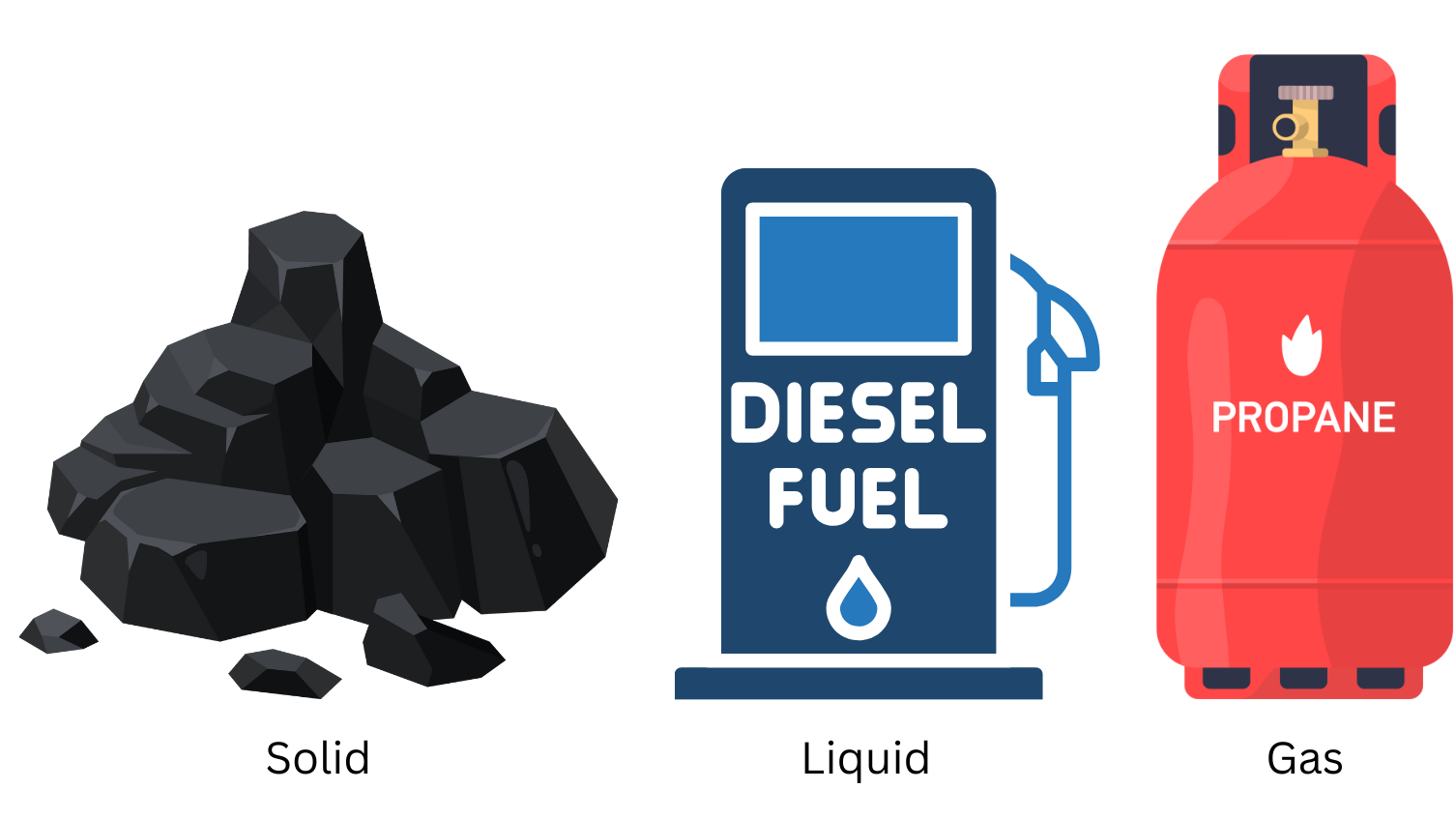

The most common fuels used in industrial combustion are made of carbon, hydrogen, oxygen, and some with traces of sulfur and nitrogen plus other inert materials. It also varies in state, like solid (coal, wood), liquid (gasoline, diesel), and gas (methane, propane). For example, natural gas contains methane (CH4), and its combustion reaction is written as:

It is essential for combustion reactions to be balanced first before going through with material balance calculations as the balanced equation is needed for the determination of theoretical oxygen needed as well as the amounts of the combustion products. Watch the video below to have an idea of how to easily construct and balance combustion reactions.

Complete vs. Incomplete Combustion

Combustion can either go to completion, producing fully oxidized products, or stop partway when oxygen is limited. This distinction is important in both efficiency and environmental impact.

Complete combustion → Maximum energy release, minimal pollutants, products in the highest oxidation state (CO₂, H₂O, SO₃)

Incomplete combustion → Oxygen-deficient, lower energy efficiency, formation of undesirable products (CO, soot, hydrocarbons, SO₂)